End-Winding Vibration Monitoring

Generator stator windings outside of the stator core are referred to as the end-winding. The end-winding is at high-voltage and requires support against mechanical vibration driven by magnetic and mechanical forces. Machine endwindings are designed so that under normal circumstances these vibrations are controlled enough to prevent significant movement. However, the endwinding support system can deteriorate due to:

Looseness of the endwinding support and tie structure due to mechanical aging and thermal expansion.

Resonance conditions close to the primary mechanical forces of rotational frequency and twice the AC line frequency.

Relative motion between one component and another which can abrade the high voltage insulation on the coils.

End-winding vibration can lead to cracking of the coil/bar insulation just outside of the stator slot and, in severe cases, may cause the copper conductors to fatigue crack leading to high arcing currents. Eventually, any of these issues can lead to stator winding ground faults.

End-winding vibration monitoring using fiber optic accelerometers provides a means to warn operators when dangerous vibration levels begin to occur.

Showing all 2 results

-

End-Winding Vibration Monitoring

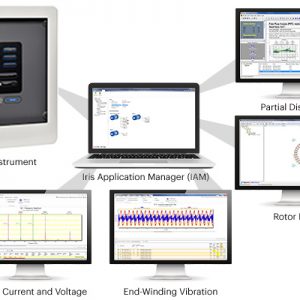

Qualitrol IRIS Power GUARDII+ – GENERATOR AND MOTOR CONDITION BASED MONITORING

The Iris Power GuardII+ is one of the most versatile and reliable condition based monitoring instrument available. It is capable of collecting data, analyzing results and communicating with third party networks about the condition of generators and motors, including continuous online monitoring of Partial Discharges, Rotor Magnetic Flux for Shorted Turn Detection, Stator End-Winding Vibration and Shaft Voltages or Current.

(0 reviews) -

End-Winding Vibration Monitoring

Qualitrol IRIS Power EVTRACII- END WINDING VIBRATION MONITORING

Iris Power EVTracII or GuardII instrument equipped with a stator end-winding vibration monitoring module provide continuous monitoring of end-winding vibration on generators and critical motors

DOWNLOAD BROCHURE EVTRACII – END-WINDING VIBRATION MONITORING

DOWNLOAD BROCHURE FOR TURBO GUARDII – MULTIPLE TECHNOLOGY MONITORING

(0 reviews)