Rotor Winding Monitoring – INDUCTION MOTORS

The most common causes of induction motor failures are due to breaks in rotor bars or shorted circuit rings due to rotor eccentricity. Current Signature Analysis (CSA) is used to accurately measure faults in the induction motor rotors through changes in the rotor magnetic field.

Current Signature Analysis is important in tool in preventing:

Broken bars that cause rotor core damage due to temperature increases and arcing.

Premature degradation of bearings due to torque and speed oscillations on the rotor.

Stator failure when broken rotor bars can lift out of the rotor slot due to centrifugal forces.

Rotor eccentricity issues due to unbalanced magnetic forces

Showing all 2 results

-

End-Winding Vibration Monitoring

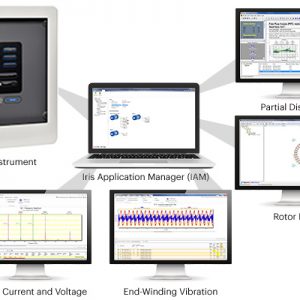

Qualitrol IRIS Power GUARDII+ – GENERATOR AND MOTOR CONDITION BASED MONITORING

The Iris Power GuardII+ is one of the most versatile and reliable condition based monitoring instrument available. It is capable of collecting data, analyzing results and communicating with third party networks about the condition of generators and motors, including continuous online monitoring of Partial Discharges, Rotor Magnetic Flux for Shorted Turn Detection, Stator End-Winding Vibration and Shaft Voltages or Current.

(0 reviews) -

Rotor Winding Monitoring – INDUCTION MOTORS

Qualitrol IRIS Power MDSP3 – CURRENT SIGNATURE ANALYSIS

Product Overview

The MDSP3 detects rotor cage winding faults including broken rotor bars, cracked shorting rings and unequal air gaps in induction motors

(0 reviews)