Rotor Flux Monitoring

Rotor flux monitoring using air gap flux probes is the most powerful means to determine if turn-to-turn shorts have occurred in the rotor winding of generators and synchronous motors. This information is critical in planning maintenance, explaining abnormal vibrations and verifying new and rewound rotor integrity.

A turn-to-turn short is the most frequent rotor insulation failure mechanism and can result in:

Thermal imbalance of the rotor pole, leading to increased mechanical vibration

Magnetic imbalance in the flux resulting in mechanical vibration

Inability to reach the rated MVA for that machine

Rotor ground insulation failure

Iris Power provides flux monitoring solutions that include a flux probe designed specifically for the air gap distance in between the rotor and stator sending data to the instrument and diagnostic software.

Showing all 4 results

-

End-Winding Vibration Monitoring

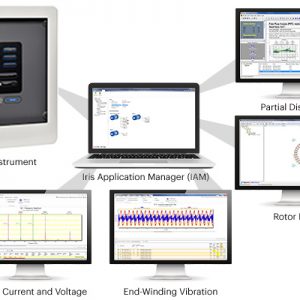

Qualitrol IRIS Power GUARDII+ – GENERATOR AND MOTOR CONDITION BASED MONITORING

The Iris Power GuardII+ is one of the most versatile and reliable condition based monitoring instrument available. It is capable of collecting data, analyzing results and communicating with third party networks about the condition of generators and motors, including continuous online monitoring of Partial Discharges, Rotor Magnetic Flux for Shorted Turn Detection, Stator End-Winding Vibration and Shaft Voltages or Current.

(0 reviews) -

Rotor Flux Monitoring

Qualitrol IRIS Power FLUXTRACII-S – ROTOR FLUX MONITORING (MOTORS AND GENERATORS)

Product Overview

The FluxTracII is continuous monitor to collect and analyze flux data from any flux probe in real time, providing the user with data on rotor winding shorted turns.

(0 reviews) -

Rotor Flux Monitoring

Qualitrol IRIS Power FLUXTRACII-R – ROTOR FLUX MONITORING (2 AND 4 POLE ROUND ROTORS)

The FluxTracII-R is continuous monitor to collect and analyze flux data from any flux probe in real time, providing the user with data on rotor winding shorted turns.

(0 reviews) -

Rotor Flux Monitoring

Qualitrol IRIS Power RFAII-S – ROTOR FLUX MONITORING (MOTORS AND GENERATORS)

The RFAII-S is a portable instrument to periodically collect and analyze flux data from any flux probe in real time, providing the user with data on rotor winding shorted turns.

(0 reviews)