- Ignition of large oil or heavy fuel oil fired burners in utility boilers

Shop

Showing 64–72 of 152 results

-

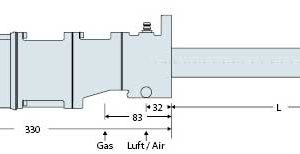

HEGWEIN Gas Burners

HEGWEIN GAS BURNERS Heat release max. 4500 kW

- Guaranteed electromagnetic compatibility

- No high-voltage cable required on site

- Protection ratings of IP 54 (standard) or IP 65 (special version)

- Rugged, low-maintenance design

- Service friendly design: All electrical components are easy to replace

- Nine burner sizes ranging from 15 kW to 4.5 MW (50,000 BTU/hr to 15,000,000 BTU/hr)

- Built-in flame rod, ideally located

- EC-approved ionisaton flame monitors and burner controls

- Fuel types include natural gas, conditioned coke oven gas, propane/butane or process gas, according to customer preference and analysis

- 1-stage, 2-stage or modulated operation

- Wide turn down ratio

- Custom outer tube lengths available in 10-mm increments

DOWNLOADS

(0 reviews) -

HEGWEIN Gas Burners

HEGWEIN GAS BURNERS Heat release max. 2000 kW

- Guaranteed electromagnetic compatibility

- No high-voltage cable required on site

- Protection ratings of IP 54 (standard) or IP 65 (special version)

- Rugged, low-maintenance design

- Service friendly design: All electrical components are easy to replace

- Nine burner sizes ranging from 15 kW to 4.5 MW (50,000 BTU/hr to 15,000,000 BTU/hr)

- Built-in flame rod, ideally located

- EC-approved ionisaton flame monitors and burner controls

- Fuel types include natural gas, conditioned coke oven gas, propane/butane or process gas, according to customer preference and analysis

- 1-stage, 2-stage or modulated operation

- Wide turn down ratio

- Custom outer tube lengths available in 10-mm increments

DOWNLOADS

(0 reviews) -

HEGWEIN Gas Burners

HEGWEIN GAS BURNERS Heat release max. 15 kW

- Guaranteed electromagnetic compatibility

- No high-voltage cable required on site

- Protection ratings of IP 54 (standard) or IP 65 (special version)

- Rugged, low-maintenance design

- Service friendly design: All electrical components are easy to replace

- Nine burner sizes ranging from 15 kW to 4.5 MW (50,000 BTU/hr to 15,000,000 BTU/hr)

- Built-in flame rod, ideally located

- EC-approved ionisaton flame monitors and burner controls

- Fuel types include natural gas, conditioned coke oven gas, propane/butane or process gas, according to customer preference and analysis

- 1-stage, 2-stage or modulated operation

- Wide turn down ratio

- Custom outer tube lengths available in 10-mm increments

(0 reviews) -

SMITSVONK Flare Ignition system

SMITSVONK FLARE PILOT BURNERS (FLAME FRONT IGNITION)

Ignition of waste gas from pipe flares, air and steam assisted flares and ground flares. For most flare systems the pilot burner can not be accessed for service. Maintenance or replacement is not possible while the flare is in operation. To safeguard operation, Smitsvonk’s pilots provide reliable ignition and stable burning even under the most difficult climate conditions.

BROCHURES

(0 reviews) -

SMITSVONK Flare Ignition system

SMITSVONK FLARE PILOT BURNERS (ELECTRICAL IGNITED)

Ignition of waste gas from pipe flares, air and steam assisted flares and ground flares. For most flare systems the pilot burner can not be accessed for service. Maintenance or replacement is not possible while the flare is in operation. To safeguard operation, Smitsvonk’s pilots provide reliable ignition and stable burning even under the most difficult climate conditions.

BROCHURES

(0 reviews) -

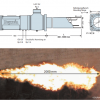

SMITSVONK Flare Ignition system

SMITSVONK FLAME FRONT IGNITION

A flame front generator is a system in which a gas/air mixture is introduced at ground level and flows up a one-inch line to the pilot burner.

After filling this line with the mixture it is ignited by a spark. The resulting flame travels to the top of the flare where the pilot burner is ignited.(0 reviews) -

HEGWEIN Dual-Fuel Igniters

Hegwein DUAL FUEL IGNITERS Heat release max. 1000/400 kW

Ignition of large oil or heavy fuel oil fired burners in utility boilers

DOWNLOADS

(0 reviews) -

DIELECTRIC OIL PROCESSING

MAXEI DIELECTRIC OIL PROCESSING

The oil deteriorates, becomes acid and turns a brownish colour. At this stage there is a real danger to the transformer as the breakdown voltage deteriorates quickly.

The regeneration process is an economic and eco-friendly alternative to changing the oil. It avoids using a large quantity of new oil and the need to manage the used oil. It reduces oil acidity, dibenzyl disulphide content and the regeneration of the oil without having to shut down the installation.

(0 reviews)